Project Description

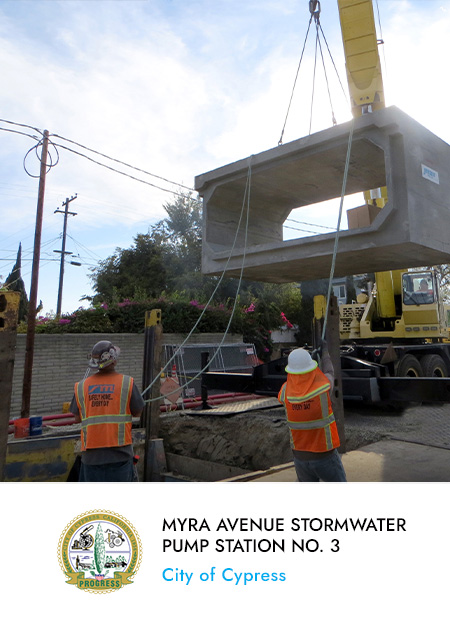

AKM prepared a preliminary design report, and provided design and construction management/inspection services for the replacement of a duplex wet well – dry well sewer lift station. The Rocky Point Pump Station collects sewage from the City’s Drainage Regions 1 and 3 (320 acres). It was a wet well/dry well facility located under the street, incorporating two (2) 50 HP, recessed impeller pumps. The pump station was in poor condition, and was recommended for upgrade in the City’s Sewer Master Plan. AKM prepared a Preliminary Design Report, developed construction documents, and provided construction management and inspection services for the project. The PDR identified six (6) alternatives to improve emergency storage capacity and reliability of the facility. The alternative selected by the City and designed by AKM included:

- New 23,000 gallon PVC lined emergency storage wet well.

- Replacement of existing pumps with new 40 HP, recessed impeller pumps with an immersible motor for a dry well application.

- New discharge piping and valves designed to accommodate dual forcemains.

- New motor control center and variable frequency drives.

- New pump station control panel.

- New wet well and forcemain aeration system.

- New dry well ventilation system.

- Sound paneling, duct silencers, and a sound control door to mitigate noise complaints from the neighbors.

- Bypass pumping system during construction.

AKM provided design and construction management/inspection services for the replacement of a duplex wet well – dry well sewer lift station. The Project included utility relocations in preparation for the work, construction of a new T-lock lined underground reinforced concrete emergency storage wet well with an epoxy/polyurethane lined floor, construction of two new T-lock lined precast concrete manholes, bypass sewage pumping while the existing pump station was taken out of service, recoating of the existing wet well with an epoxy/polyurethane coating, new ductile iron forcemain piping, gravity sewers, new valves, an aeration system, two new magnetic flow meters, new motor control center, two new VFDs, new pump station control panel, integration with the City’s central SCADA system and coordination and review of testing, startup and training activities.

Project

Client