Project Description

The Walnut Pump Station services a drainage area of 0.48 square miles of primarily single-family residential land use. Pump station capacity is 360 cfs.

West of the pump station, stormwater is conveyed to the facility via 27-inch and 60-inch storm drains. Stormwater collected on the east side of Talbert Channel is conveyed beneath the channel by a 54-inch pipe. All stormwater collected at the Walnut Pumping Station is discharged to Talbert Channel.

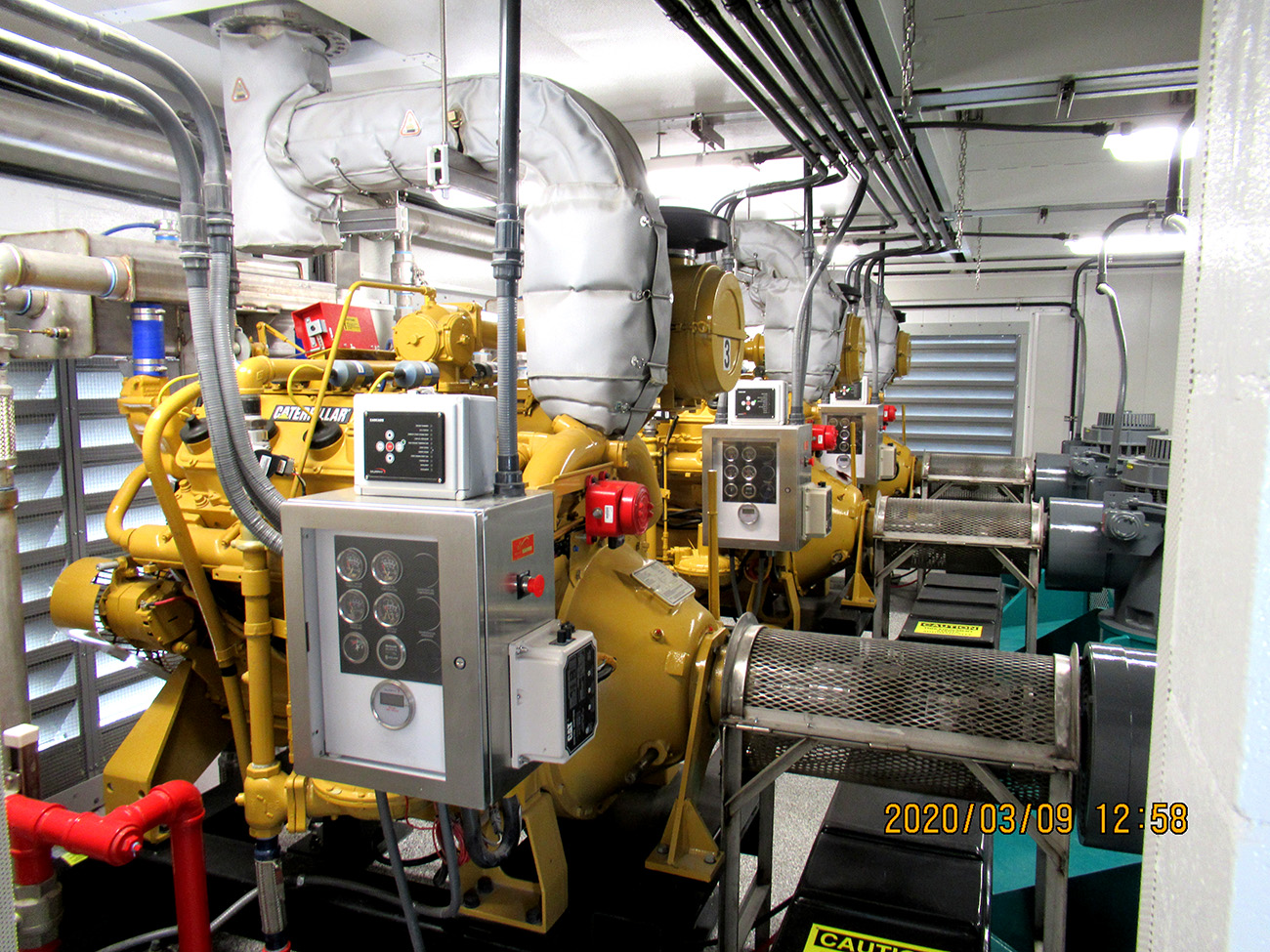

The Pump Station was originally constructed in 1964, and was enlarged to its current 4-pump configuration in 1979. It consists of a small block building housing natural gas engines and pumps, a below-ground sump, and a paved yard. The facility is enclosed by a block perimeter wall which is also a common wall with single-family residential homes to the north and west.

The existing station’s equipment was original (50 years old) and obsolete. Repair parts for the engines could no longer be obtained, and the pumps’ column and bowl assemblies had experienced significant corrosion, and were near failure. The facility’s redwood trash rack was largely ineffective, causing periodic pump clogging and the pumping of debris to the downstream channel. The existing electrical equipment, also original to the facility, had also become obsolete and potentially hazardous to operate.

AKM prepared a Deficiency Report for the facility which summarized all of the facility’s issues, risks to the community, and provided a recommended implementation schedule for presentation to City Council for funding. A Preliminary Design Report was also prepared, which provided greater detail regarding the station’s capacity and condition, and recommended improvements to rehabilitate the existing facility in lieu of constructing an entirely new pumping station.

AKM prepared construction plans and specifications based upon the PDR recommended improvements which included all new electrical, mechanical, and control equipment; new 316 stainless steel trash rack; modernization of the existing building; urban run-off diversion system to the local sewer; SCADA control through the City’s fiber optic network; new site paving and entrance gate; and new air condition electrical control building with bathroom facilities.

Mechanical Improvements

- Four (4) CAT 3408, 18 liter, natural gas engines (250 hp each)

- Four (4) Cascade 42 AP propeller pumps (40,000 gpm each), with 3:1 reduction ratio right angle gear driveone (1), 10 hp, recessed impeller, nuisance flow submersible pump

- Urban run-off diversion piping to the local sewer

- New natural gas service, coordinated through SCG Company

Electrical Improvements

- New 480 volt, 3 phase electrical service

- New motor control center

- New PLC based control system

- New engine control panel

- New sump pump and building fan control system

Building Improvements

- New air conditioned electrical building with bathroom

- New roofing system with equipment removal hatches

- Stucco coating of building exterior and perimeter walls

- Sound paneling on all walls and ceilings

- New acoustic doors and louvers

- New 316 stainless steel trash rack

The project was developed so that the station improvements could be constructed during the non-rainy season (April – October). Extensive planning was performed during the design phase to ensure the project was bid far enough in advance to ensure long lead time equipment would be delivered to the site in time to complete the work within the required construction window.

AKM also provided engineering support services during the construction period and start-up services.

Project

Client