Project Description

Edinger Well was planned and constructed to replace the capacity lost in the aging wells in the south portion of the City’s system. The well has a 20-inch 304 stainless steel casing with Ful-Flo louvers with 0.06-inch slots between 500 and 840 ft bgs.

AKM prepared plans, specifications, and estimates for the equipping of the new well. The 2,000 gpm well facility is located on the same lot as the Fairfield Inn & Suites Hotel, adjacent to the 55 Freeway.

AKM utilized the City’s hydraulic model and conducted analyses to select a 450 HP, 6-stage well pump rated at 2,000 gpm at 615 feet TDH to provide efficient service with varying groundwater levels. The well’s production is conveyed to the distribution system through 225 LF of 12-inch CML ductile iron pipe.

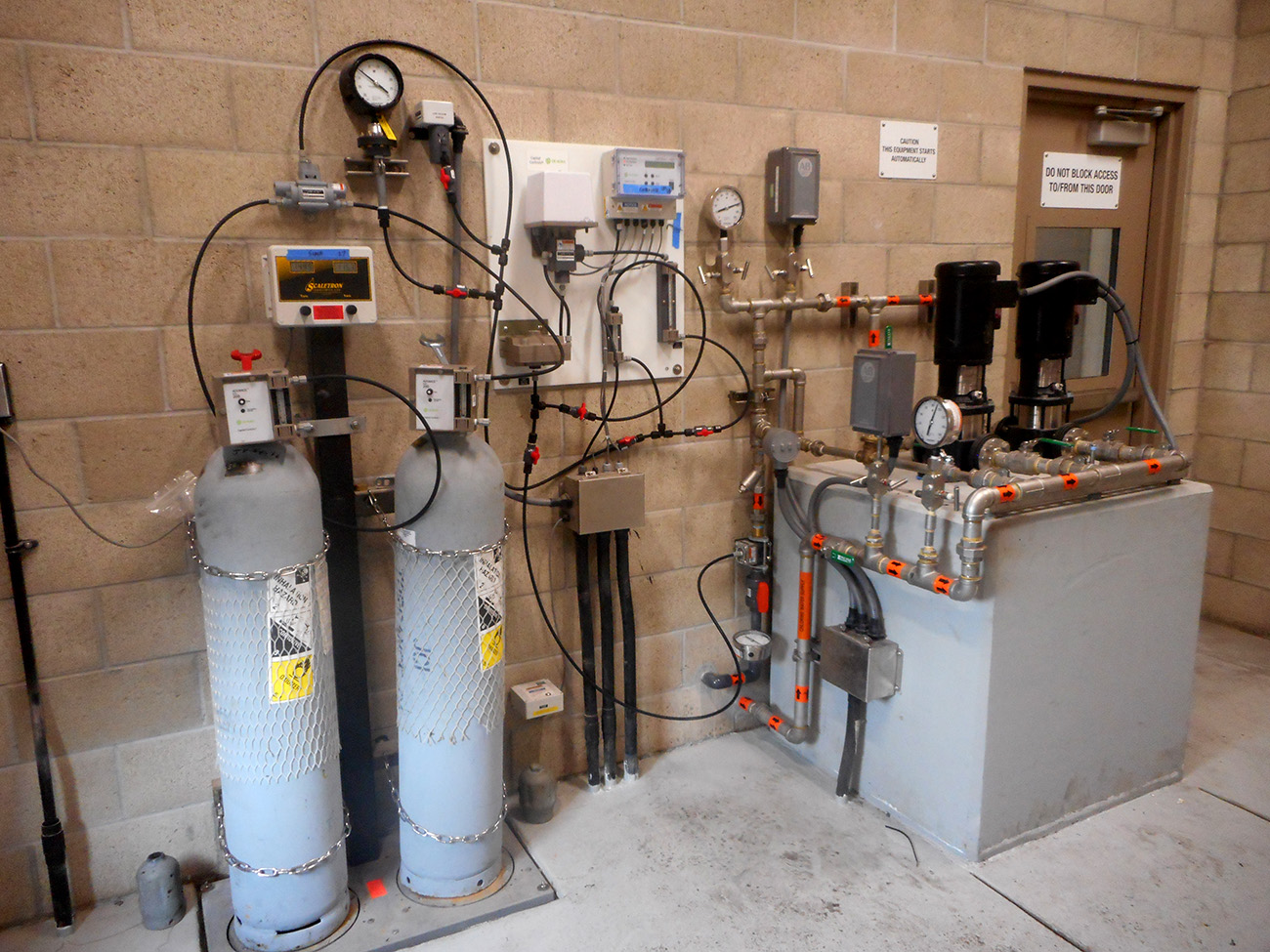

Chlorine gas is used for disinfection (City Standard). The chlorine system consists of two gas tanks, water supply booster pumps, control panel, and emergency scrubber system.

Backup power for the site is provided through a 600 kW emergency diesel generator with sub-base fuel tank, alternator, automatic transfer switch, diesel particulate filter, and super critical grade silencer.

The electrical components of the well building include a 1,000 amp switchboard, including a 450 hp variable frequency drive with a solid state bypass starter. Also installed are the well pump control panel and RTU. The local PLC control system was fully integrated with the City’s master SCADA Ethernet network, using Allen Bradley equipment through leased telephone lines. Local and remote OIT screens were developed to provide full monitoring and control of the facility. The well equipment is enclosed in a 2000 square foot building, which includes sound panels on the walls of the pump room. The exterior of the building features stucco and was designed to blend in with the surrounding hotels.

AKM provided engineering services during construction, and participated in testing and commissioning of the facility.

Project

Client