Design

Construction Management/Inspection

AKM Consulting Engineers provided construction plans, specifications, estimates, along with bidding and construction inspection/management services for both the drilling and equipping of Well 31, along with improvements to the existing booster pump station, Well 28, and the adjacent reservoir within the facility. Well 31 was designed to replace Well 23, which had reached the end of its useful life. The water produced by Well 31 is typically blended with Well 28, which has nitrate levels exceeding the maximum contaminant level (MCL), before being conveyed to the Lampson Reservoir, where it is then pumped into the distribution system. The Well 31 pump and variable frequency drive (VFD) were selected to allow for both direct pumping into the closed distribution system and conveyance to the adjacent reservoir.

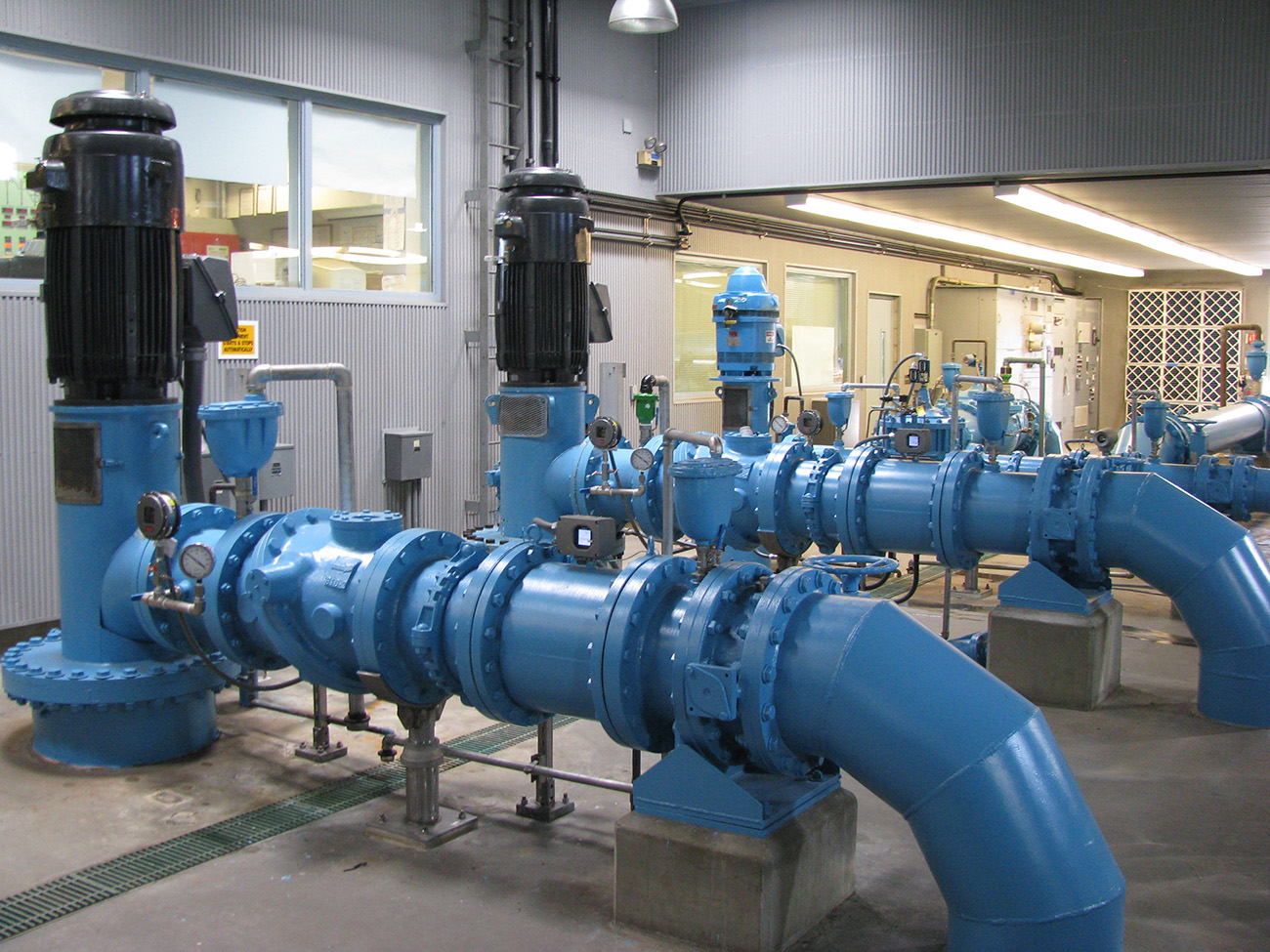

The project included the installation of a 500 HP, 3,500 GPM deep well vertical turbine pump in the well drilled by the City during Phase 1 of the project. The scope of work also included the installation of 16-inch cement mortar-lined and coated welded steel discharge piping, connecting both to the City’s distribution system and the reservoir inlet piping. Additional piping and valve installations included three CLA-VAL control valves. A pre-fabricated metal-framed roll-apart well building was constructed to house Well 31’s electrical equipment and wellhead. Electrical improvements included an 18-pulse VFD with a bypass solid-state starter, a single-phase lighting transformer, a motor control center (MCC), a power monitor, and a main disconnect. Instrumentation installations included four magnetic flow meters (10-inch through 20-inch), a well-level transmitter, a high-discharge pressure switch, and a discharge pressure transmitter. The existing Booster Pump Station PLC was reprogrammed and control screens were developed to enable variable-speed operation and automated control of Well 31, which was also integrated with the City’s SCADA system.

Additional site improvements included the construction of a storm drain junction structure and catch basin, installation of a precast discharge-to-waste substructure, and conversion of two existing booster pumps to variable-speed operation. This required installing two new 200 HP inverter-duty-rated motors and two new VFDs, as well as a new starter for the booster pump station jockey pump. Electrical upgrades included a new 2,000-amp MCC section, the replacement of a nitrate sampling pump, and the installation of a 7-foot piping extension to the existing reservoir inlet piping inside the existing reservoir. The project was completed with full asphalt concrete re-paving throughout the facility.

During the drilling of Well 31, AKM also provided inspection services for the installation of a nitrate monitoring and control system, designed to automatically blend water from Well 28 and Well 23 to maintain nitrate levels below 80% of the MCL. This work included replacing the existing 200 HP solid-state starter at Well 28 with a VFD, modifying the existing control system to enable automatic modulation of Well 28’s capacity, and installing stainless steel piping for monitoring equipment, which was then integrated into the SCADA system.

All tie-ins, shutdowns, and electrical work were closely coordinated with the City’s operations staff to minimize service interruptions, as the work took place within an active reservoir and pumping complex containing two reinforced concrete reservoirs, two existing wells, a booster pump station, and a disinfection facility.